Printed electronics is, as you must have already realized, a vast and dense section of the screen print industry. To understand it in depth, and more holistically, we spoke of looking at the various applications of PE in the different verticals, the different industries that exist today. With the outbreak of the COVID – 19 pandemic, there’s nothing more befitting, more relevant than the healthcare industry. Here’s a look into the role of printed electronics in the ever – important healthcare industry!

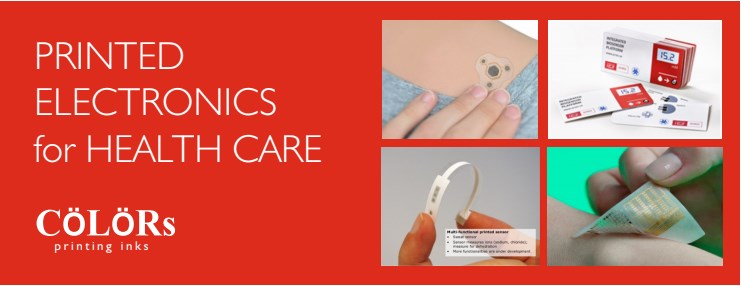

Printed Electronics for Health Care

Printed Electronics has shown tremendous potential in health care sector. Here certain components like sensors and electrodes used in medical monitoring, diagnostic, and sensing devices can be manufactured at a fraction of cost as compared to non printed (conventional) devices. These are not only cheap, but are flexible and sturdy to be used in various areas. Current application of PE focuses on the below mentioned areas –

-Smart Cards

-Packaging

-Wearables

Smart Cards

Biosensors have been used in health care industry since 1960’s. They are used for monitoring vital signs (e.g. heart rate, body temperature, blood pressure); for testing metabolic variations (e.g. blood glucose, cholesterol, lactate); and for detecting pathogens elements (e.g. bacteria and virus). Recent developments in the design and application of PE has converted these simple sensors to next generation Smart Cards which can help users to check information on their glucose, stress, lactate and hormone levels. It can also allow access to patient’s database linking the previous history to functioning of body vitals and suggesting suitable treatments.

Dr. Turner and his collaborators at Acreo Swedish ICT have developed a unique measuring instrument which is screen printed and is as small as a business card. This smart card contains biosensors which can analyze blood and saliva samples and gives a digital reading or can send results to your mobile phone immediately. This has incredible application in far off areas where basic care is not available and immediate decisions need to be taken.

Medical Packaging

PE has made in roads in packaging section also. Imagine if the carton can speak and give details like the time to take medicine, the dosage and availability. This would be very useful to elderly patients as they may forget to take medicine or cannot differentiate between several packs. MID Sweden has developed a packing which when touched can tell you its name and prescription.

In this carton the circuit and sensor is printed behind the word “MEDICIN”.

Similarly a company SVC Techon has produced a blister pack (compatible with NFC and RFID) which can intimate patient / pharmacy or health care giver, real time data on amount of medicine pill consumed on their mobiles. Once the last pill is removed, a message is send to the concerned party and appropriate action can be taken.

Wearables

As the name suggests these circuits (complete with sensors, electrodes, conductive inks, TFT) are printed on Paper, Fabrics or plastics and can be worn as a patch like a second skin. They are so flexible, versatile and highly portable that it can be attached to different parts of the body to measure/ detect and transmit human vitals wirelessly to either mobile to dedicated instrument. For example a sensor in the patch can detect tiny changes in pressure which can be used to monitor blood pressure, heart rate and wrist pulse.

Park et al from UNIST – Korea has developed smart contact lens which detects glucose in human tear and can help in Diabetes treatment.

I hope this was an insightful read for you, and once again – if you have any suggestions, questions or comments, please feel free to get in touch! The article is only a curation of information already available (the sources are mentioned in text), I have only put together the findings of the fabulous work being done worldwide in PE in the healthcare industry.

Mustafa Kapadia,

He is a founder and director of COLORs – a specialised printing ink manufacturing company. He has done Master of Science – Chemistry and MS – Resource Economics (USA). Currently, He has pursuing PhD at Institute of Chemical Technology with focus on developing novel resins for UV inks.